With over 40 years of experience in the industry, we have gathered the best practices and defined a new standard for machining processes. By doing so, we are able to offer the best assortment of services to fit your every need.

Additional Services

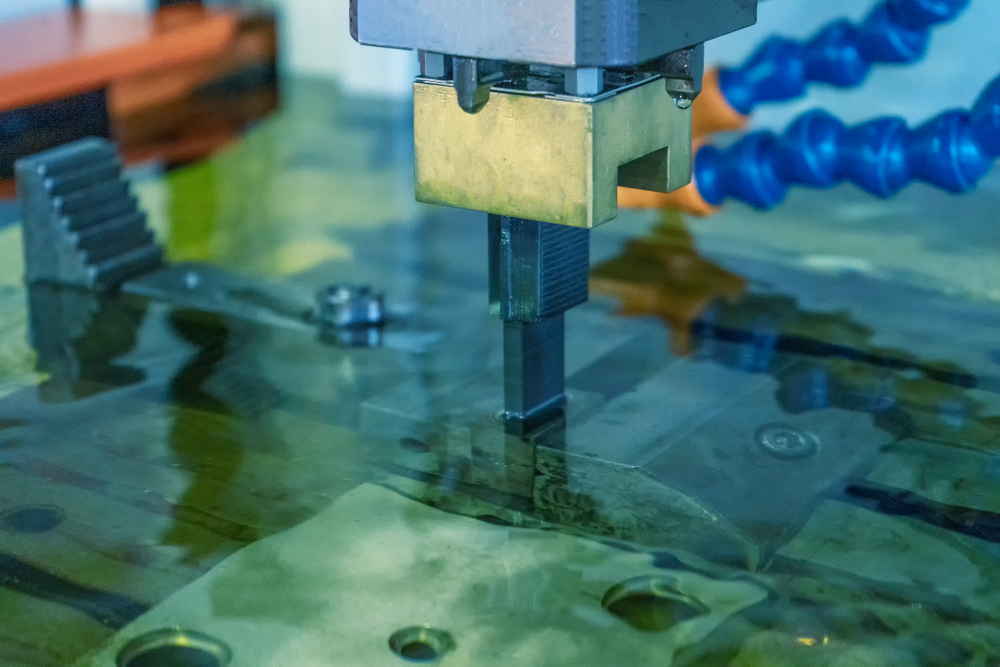

Plastic Molds

High precision plastic molds built from the ground up or from the end-product

Assembly

Assembly services for your manufactured parts including spot welding when needed